G3F Sensors: a family of laser line triangulation devices designed for operators performing quality control. Miniaturized, portable, wireless, ergonomic IoT devices for industrial use, extremely versatile and configurable.

1 – manual use by operators

2 – installation on robot for automatic handling

3 – fixed installation on supporting brackets

G3F Features

- Portable and ultra-ergonomic design

- Small and lightweight, it can easily fit in your pocket

- Wireless and IoT device

- smart communication to the factory plant

- Fast measurements

- Less than 1 s for a single measurement

- One laser, multiple surfaces

- The 405 nm laser makes it possible to efficiently measure on different surfaces, including transparent and reflective materials

- Eye safety

- G3F ensures operator safety conditionally switching on/off the laser beam

- AI Engine

- G3F runs patented AI algorithms for measurement uncertainty management

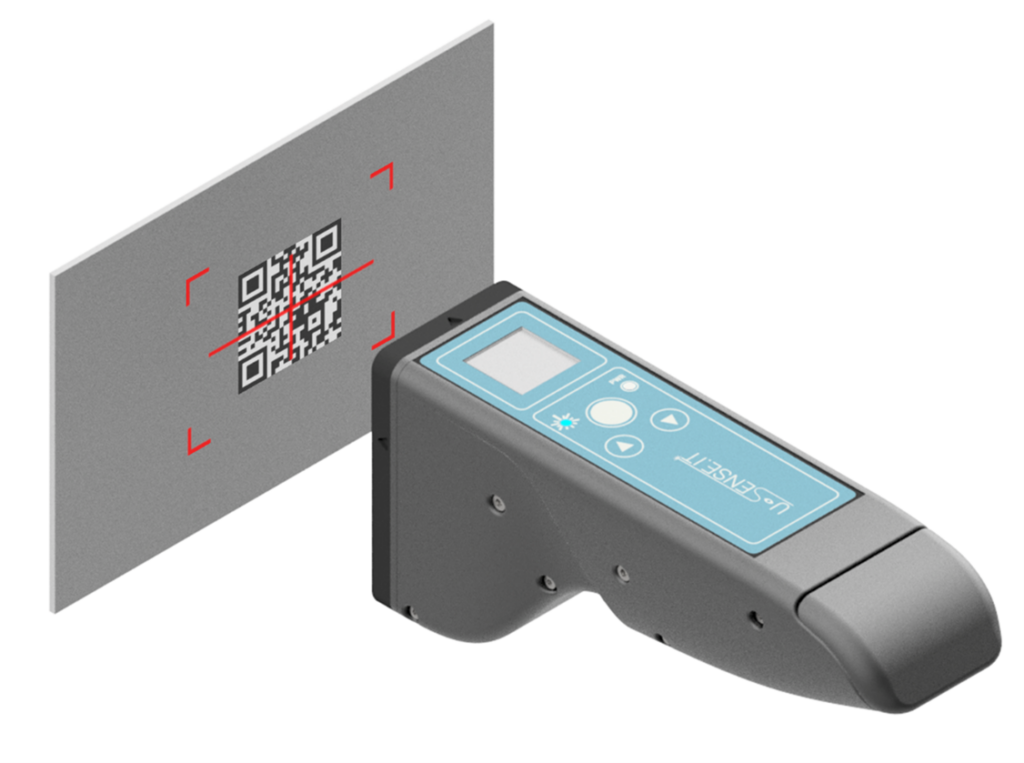

- QR/Bar code reader

- For part ID tracking

- Integrated colour sensor

- For image quality optimization

- Rechargeable removable battery

- Assures no stop operation

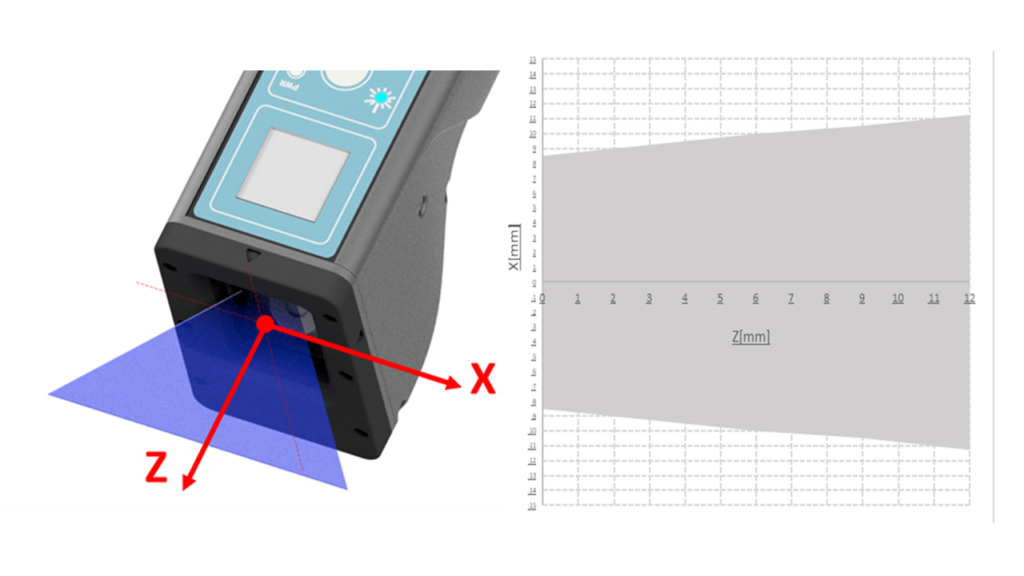

Technical Specifications of G3F

| Laser (class 2M – EN 60825-1) | 405 nm |

| Measuring range X (lateral) | 17 mm (@Z=0 mm) ……… 22 mm (@ Z=12 mm) |

| Measuring range Z (axial) | 0 …… 12 mm |

| Resolution X | 7 𝜇m (@Z=0 mm) ……. 9 𝜇m (@ Z=12 mm) |

| Resolution Z | 9 𝜇m |

| Display | 1″ integrated display |

| Dimensions – envelope (ergonomic shape) | 48 x 75 x 165 mm |

| Weight | 350 g |

G3F Solutions

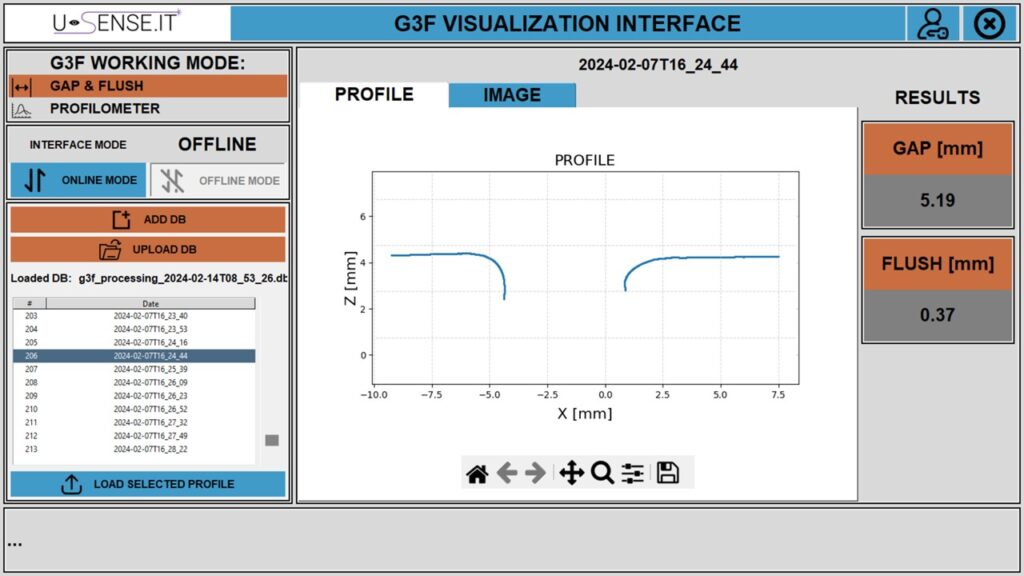

G3F-profile– portable laser line profilometer for the measurement of geometric profiles in various industrial sectors (automotive, appliance, aerospace, furniture, ………)

G3F-gap&flush – portable sensor for the measurement of gap&flush in different industrial sectors (automotive, appliance, aerospace, furniture, ………)

G3F – custom – customized solutions developed for specific customer requirements – contact us !

G3F System

The G3F system is designed for a customized, flexible and comprehensive approach for any specific application, from inline quality control, to quality laboratories and product development in manufacturing environments.

- one or more G3F sensors connected to the network

- SW HMI for display and analysis of geometric measurements

- a set of accessories for alignment or mechanical mounting

Accessories. All G3F sensors may be equipped with specific accessories, in order to assure proper positioning of the sensor with respect to the target. Alignment masks are specifically designed for the task, are made in polimeric materials of different stiffness by additive manufacturing and are mounted in front of the sensor. Supporting brackets can be realized as well for fixed and/or removable installations.