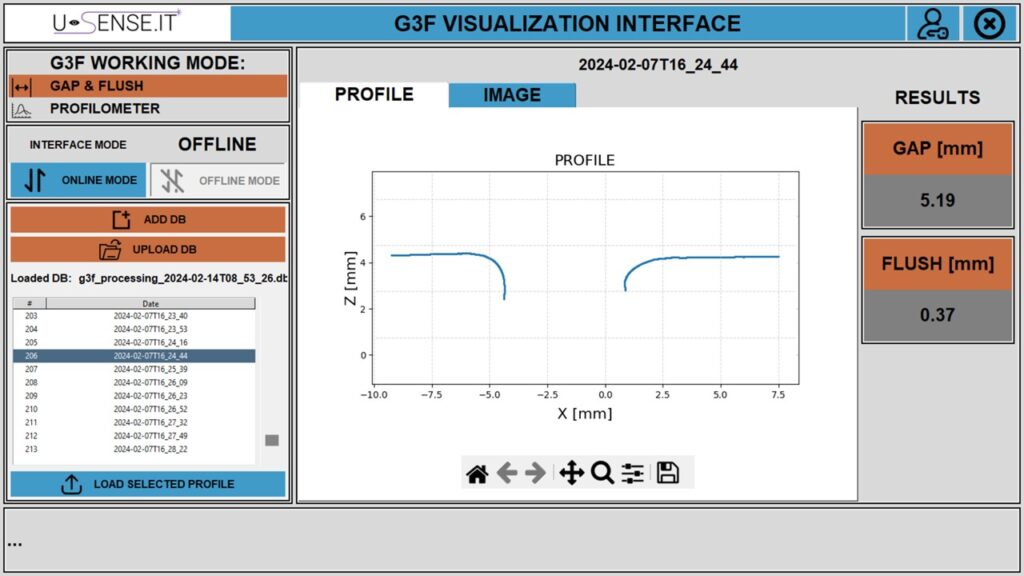

Portable laser line triangulation sensor, wireless, “smart” for Gap & Flush measurement. Specifically designed for operators performing in-line quality control.

Have a look at G3F Gap&Flush in action ! VolksWagen Autoeuropa is using a series of G3F devices to measure gaps and flushes in Final Assembly, within the European Project openZDM: LINK TO VIDEO (from minute 1:24).

Gap and Flush

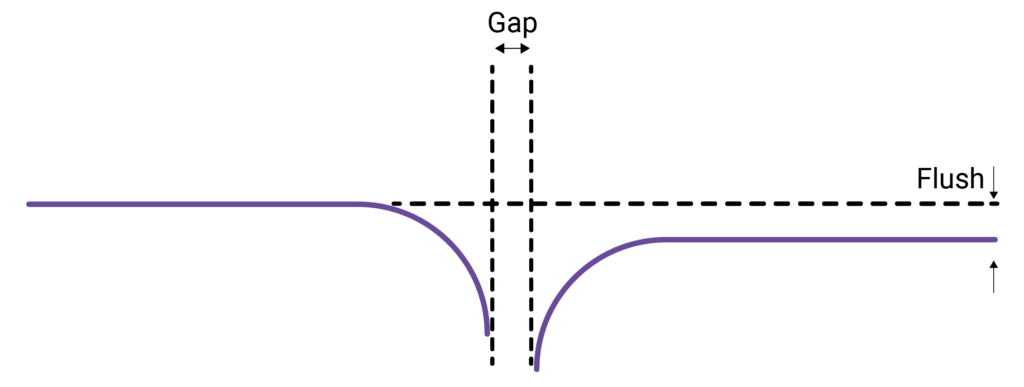

Gap: distance between two adjacent panels.

Flush: step existing between the two panels.

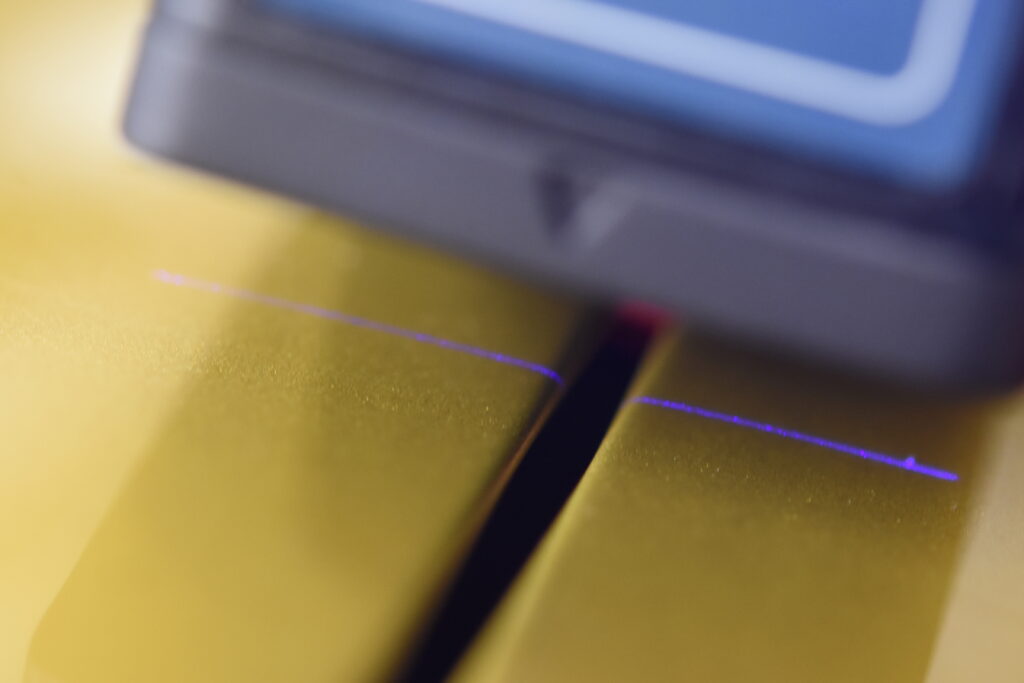

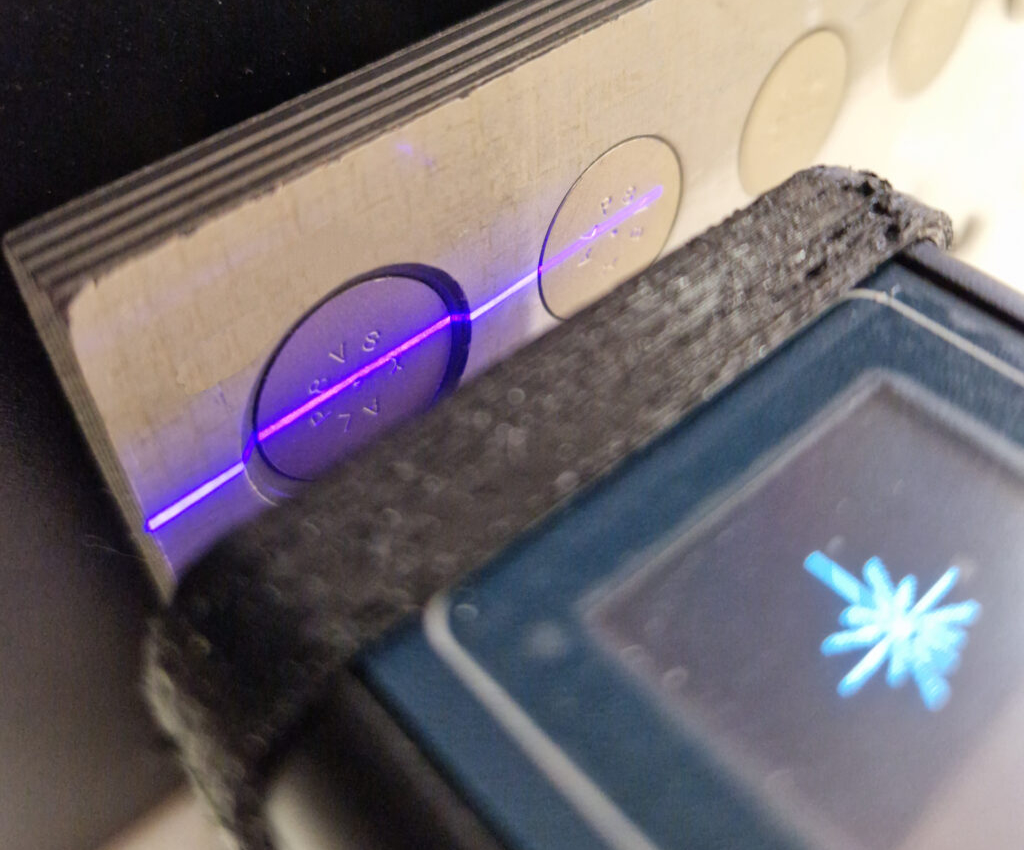

The G3F device

Thanks to its patented AI algoritms, G3F measures on any surface: metal, plastic, glass and more; no matter for surface finish, colour, gloss, reflections or transparency.

Application sectors

Hereafter some typical examples of gap/flush measurements -contact us for specific sectors of your interest !

Automotive – G3F can be used by the operators in the Final Assembly line, to measure the gap and flush between different parts of the car body.

Household appliances – G3F can be used by the operators to measure the gap and flush between the front panel and the door of the oven.

Aeronautics – G3F can be used by the operators to measure the flushness of the fasteners mounted on the aircraft